Cutting Process

- Login

- Choosing a Job Task

- Loading Material

- Completed Process

- Quality Control

- Advanced Cutting

- Guidelines to Remember

Login

- Login using credential given by the administrator

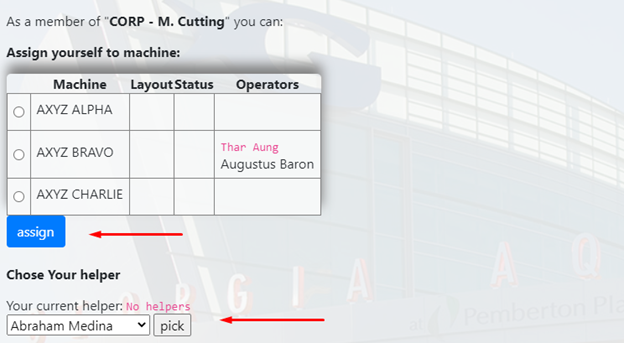

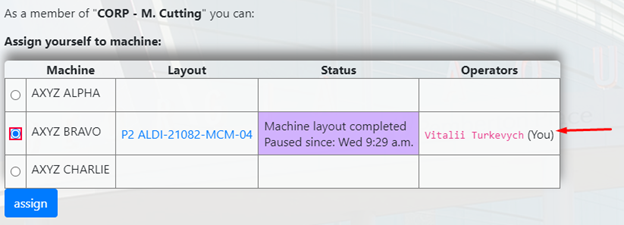

- After login, assign yourself to the corresponding cutting machine

- You can override any other user using the machine, if need be

- Assign a helper to the cutting machine

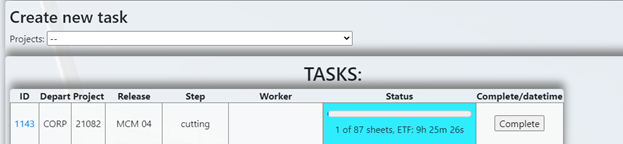

Choosing a Job Task

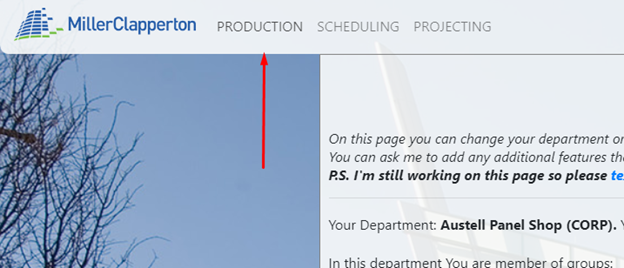

- Click the Production tab (Top of the page)

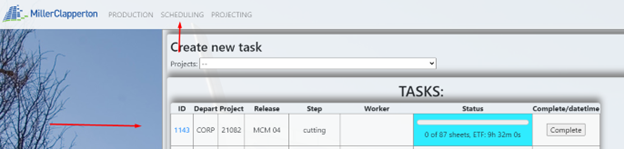

- Choose task according to what is scheduled

- Alternatively, the Schedules tab (Top of the page) shows tasks by most recent

- Choose link for Program Nest Layouts (ID Number)

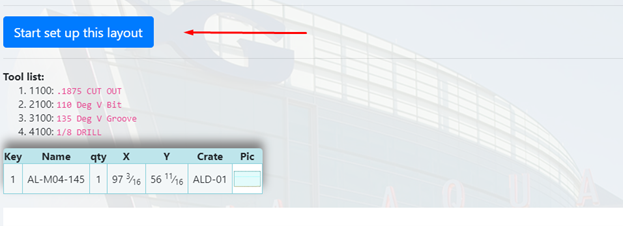

- Click START THIS LAYOUT button to reserve the task before quality checks and confirm by clicking OK

- Background should turn brown to show task is reserved

- If this button is not shown, the machine is not assigned.

- Click on the name profile in top right corner to go back and assign the machine

- Click the material needed for the job task

- Check to make sure the toolset and information is correct and working properly

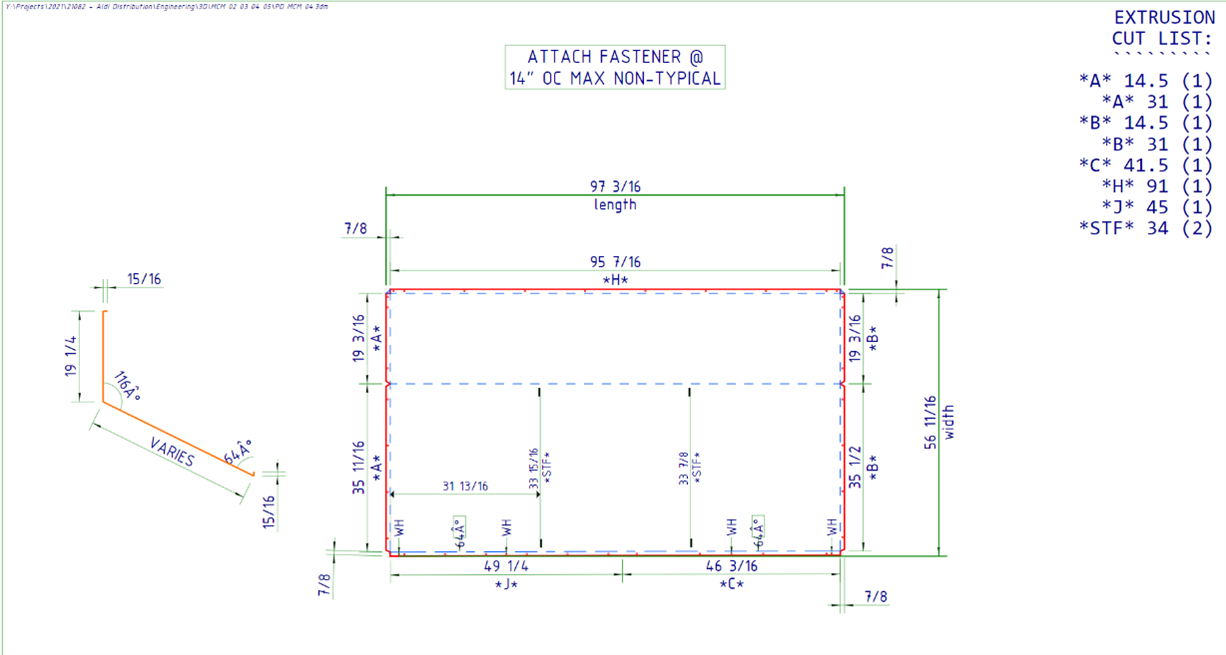

- Display the part drawings for the task by clicking on the word PIC

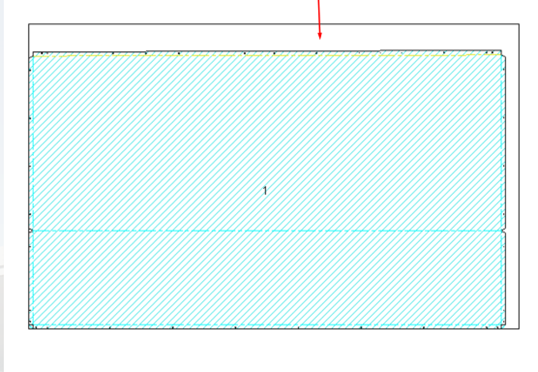

- Make sure picture below task layout matches the picture on the machine itself

- Check line depth colors

- If it does not match, check machine for correct program

- If it still does not match, check with cutting programmer

Loading Material

- “Material loaded” means material is already loaded on the machine and ready to go

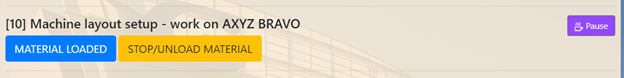

- Start by pushing button on the machine and in the same instance, click “Material Loaded” from the program

-

Once the process starts, the background turns green to show task is working to be complete

- Click “Stop/Unload Material” to interrupt a job before it is completely finished

- This releases the task from the machine

- DO THIS ONLY IF MATERIAL IS NOT DAMAGED!!!

- Click the name profile in the top left goes back to the assignment screen and shows what tasks are in progress and who is working on said task

- By clicking “Pause,” this will stop progress from the task temporarily for lunch or break when the machine is unattended. Click “Resume” to begin again

- The background will turn PURPLE when Paused

- On the assignment screen, the time will be recorded of how long the machine was paused and by which operator

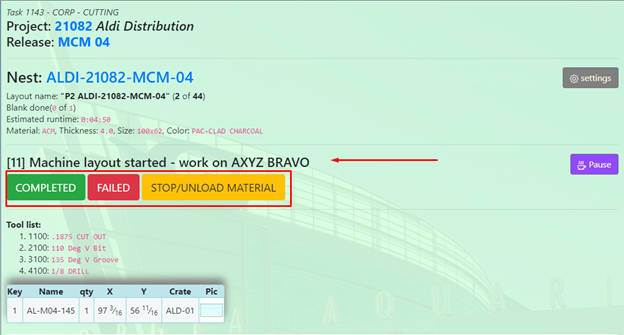

Completed Process

- Once the cutting task is completed, the program will display results to choose for the cutting task.

- RESULTS:

- COMPLETED: When the task is complete with some or no errors

- FAILED: Incomplete/Everything fails (material can no longer be used)

- Click “Complete” when cutting task is done with some or no errors

- The background changes to BLUE and shows option to choose Complete or Fail

- If multiple cutting tasks, click which tasks are completed and which failed

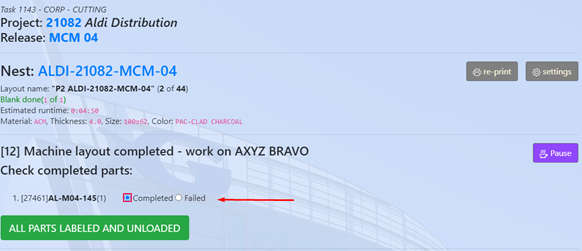

Quality Control

- Quality Control is one of the most important steps in this process

- Make sure label matches Panel number

- Make sure all panels are checked complete or fail

-

Make sure label is placed in an appropriate area where it can be seen and not hidden, even when folded (Usually the biggest area of the panel)

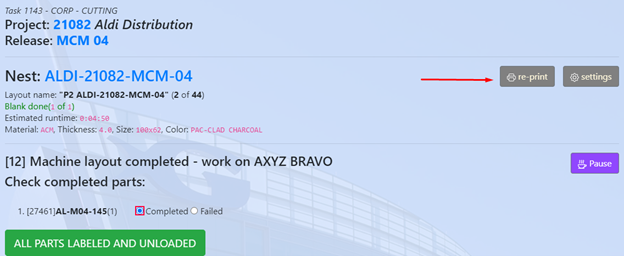

- Once quality control is complete, click “All Parts Labeled and Unloaded”

- Click “Reprint” for any labels that may be damaged or unreadable

- Once completed you will get a notification window

Advanced Cutting

- To assign multiple machines to do multiple tasks at once, click on name profile in top right corner of the program and assign to multiple cutting machines.

- This also allows one to go back and forth between all assigned machines

- Click on each task to go back and forth

- Dividing total time completion by number of machines running at the same time

- Make sure labels match multiple materials by job number

Guidelines to Remember

- Always check to make sure your name is by operator. If not, assign to a cutting machine

- Follow each task as directed and do not click ahead of the assigned task

- This causes error within the program

- Slow down and go by the manual. This will make the program and process go smoothly

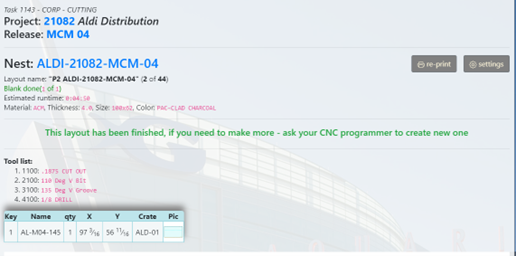

- If material has not been properly laid out and reserved in the program correctly, once completed you will NOT have the opportunity to add more.

- Done tasks will show at the bottom of the task list

- DO NOT RUSH THROUGH THE PROGRAM PROCESS!!